Page 5 - DV-series

P. 5

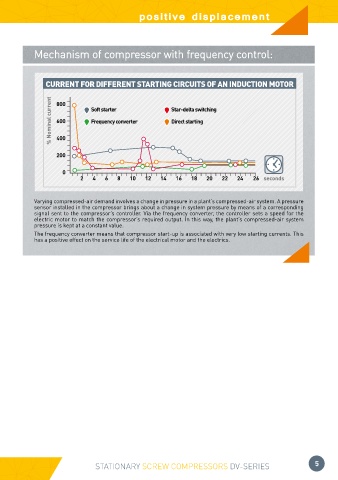

Mechanism of compressor with frequency control:

CURRENT FOR DIFFERENT STARTING CIRCUITS OF AN INDUCTION MOTOR

% Nominal current 800 Soft starter Star-delta switching

600

Direct starting

Frequency converter

400

200

0

2 4 6 8 10 12 14 16 18 20 22 24 26 seconds

Varying compressed-air demand involves a change in pressure in a plant’s compressed-air system. A pressure

sensor installed in the compressor brings about a change in system pressure by means of a corresponding

signal sent to the compressor’s controller. Via the frequency converter, the controller sets a speed for the

electric motor to match the compressor’s required output. In this way, the plant’s compressed-air system

pressure is kept at a constant value.

The frequency converter means that compressor start-up is associated with very low starting currents. This

has a positive effect on the service life of the electrical motor and the electrics.

www.comprag.com STATIONARY SCREW COMPRESSORS DV-SERIES 5