Modular adsorption dryers ADM

volume flow up to 1,5 m3/min

Specifications

| Air flow* (m3/min) | 0.5 - 1.5 |

| Max. working pressure (bar) | 16 |

| Screw connection | 1/2" |

| Rated voltage (Phase/V/Hz) | 1/230/50 |

* Measured according to ISO 7183

Comprag modular adsorption dryers ADM are highly efficient systems for drying compressed air. They are able to maintain a constant pressure dew point of -40 °C. Adsorption dryers consist of two aluminium profile columns that contain the optimal amount of moisture adsorbing desiccant. Compressed air slowly flows alternately into both columns and is brought into contact with the desiccant, removing the moisture from the air. After a set time, the desiccant in one column becomes saturated and the compressed air flow switches to the other column, which now takes over the drying process. During this time, the saturated column is dried using an adjustable amount of purge air. Switching between both columns takes place with a preset optimal cycle time of 10 minutes.

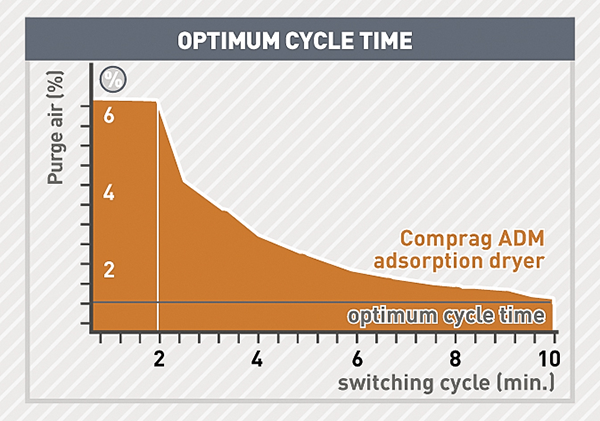

Optimum cycle time

Comprag Adsorption dryers work at optimum performance with a cycle time of 10 minutes. If the switching time is reduced, the operational load on the dryer, the valves and the desiccant increase. In addition, the pressure drop increases when the operating pressure in the regenerating column is equalized more frequently. A two-minute drying cycle, in which the column is regenerated with dry compressed air, briefly occupies about 7.5% of the dried air. Comprag Adsorption dryers ADM, using a 10-minute cycle, only use about 1% of the total cleaned air on average.

- Fully automatic operation

- Constant pressure dew point of -40 °C for efficient moisture removal

- High-quality desiccant with high specific surface

- Manual purge air adjustmen

- Optimum cycle of 10 min

Downloads